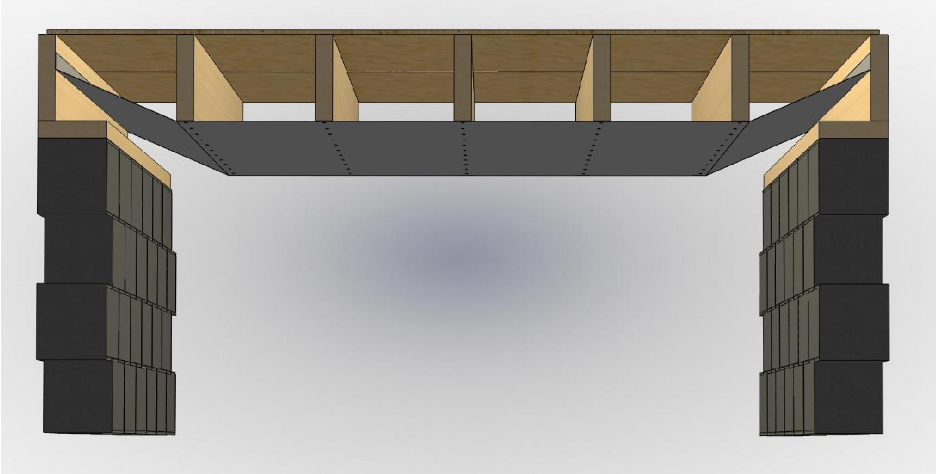

The only difference between a radiant barrier and a reflective insulation is that a reflective insulation has an R-value. The R-value is achieved by having the low-emissivity, high-reflectivity surface face into a dead air space. While some products also have a layer of insulation laminated to a low-e surface, that insulation layer is typically just an R-1, so even those products still rely on the dead air space.

The FTC (Federal Trade Commission) R-value Rule allows the R-values of reflective insulation products to be tested and marketed two ways.

- The product can be sent to a testing lab, which will construct a mock-up assembly representative of how the product will be installed in the field (or example between wall joists or under a crawl space) and run a test measuring the BTUs of energy lost when the temperature, air flow, direction of heat, and all other factors are accounted for.

- Manufacturers to just use numbers in a table provided by ASHRAE (the American Society of Heating, Refrigeration and Air-conditioning Engineers), which has the exact R-values for low-e surfaces facing into different sized dead air spaces, under different temperatures and different directions of heat flow. This seems simple enough, and most manufacturers are happy to measure the exact emissivity of their product and find the corresponding number in the table to list as their R-value.

However, things get complicated when the emissivity of the product changes over time due to corrosion. As explained in the previous blog post on corrosion, when aluminum is exposed to heat and humidity over time, the emissivity increases (and the reflectivity decreases accordingly). A higher emissivity means a necessarily lower R-value, all other factors being equal.

Testing radiant barrier and reflective insulation products for emissivity before and after corrosion testing revealed that, while some products corrode less aggressively than others, nearly all aluminum products corrode to some degree. One popular product made with aluminum foil had it’s emissivity increase from 0.03 to 0.08 (97% to 92% reflective) after 15 minutes exposure to high heat and humidity while another increased to nearly 0.4 (60% reflective). The corrosion can be even more aggressive if liquid water (or condensation) is involved.

For example, let’s say a single-sided reflective insulation with an initial emissivity of 0.03 is installed in a 2x4 crawlspace. The heat flow is down, the air temperature is a steady 50 F with a 30 F temperature difference on the other side. You would get an insulation value of R-9.60. Now if that product were a coated aluminum metalized film or aluminum foil that saw some humidity, and the emissivity increased to 0.05, you wouldn’t think it would make a big difference in R-value. However, that small change in emissivity brings the total R-value down to R-8.17. Now suppose this product is an aluminum foil that sees some water. According to ASHRAE, when just a little condensation is visible on aluminum foil, the emissivity can reach 0.2 to 0.3, which would decrease that R-value down to R-3.86. Then take the worse case scenario that maybe your low-e surface is made with an unprotected, uncoated metalized film and has an emissivity of about 0.50. We’ve seen the aluminum on an unprotected film completely oxidize in high heat and high humidity environments. In that case, the R-value would drop to R-1.88. Now your product has just lost over 75% of its R-value and you’ll have to re-insulate all over again.

Unfortunately, reflective insulation manufacturers don’t mark an “aged R-value” so the consumer doesn’t know to expect lost performance over time. If the reflective insulation gets installed in an application where it’s not visible, the customer won’t know it’s a problem until it’s too late. So as a consumer what can you do about it? Well, for one you can look to only buy products from manufacturers that run extensive testing and can show the stability of their products over time, or at the very least, only buy products with multi-year warranties so you won’t be out the money if or when it does need to be replaced.

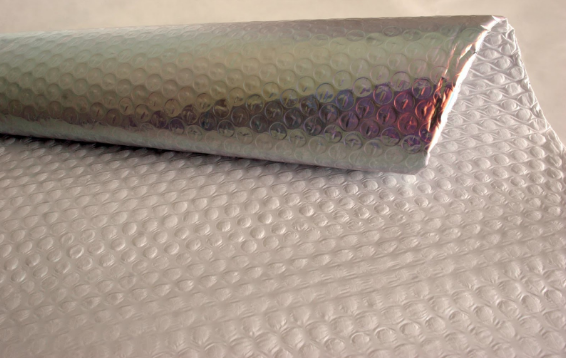

One such product is Sigma’s Thermflux 3100 Series. This product holds up better to corrosion than all other aluminum products tested (including a wide variety of aluminum foil and metalized film laminates) because Sigma tests each and every roll they make to an aggressive, accelerated corrosion test. This product starts off at 0.04 emissivity (96% reflective) due to the protective coating over the aluminum and holds its emissivity (and R-value) under laboratory tests with 100% humidity condensing on the aluminum and heat so high it starts to shrivel the material. (If your house ever gets that hot, you have bigger problems than the R-value of the insulation.)

Another solution to the corrosion problem is to use a product that isn’t made with aluminum at all. Sigma’s new Copperflect copper reflective insulation is made with 99.99% pure copper and no aluminum whatsoever. Copper, like gold, is considered a “noble metal” because it is so resistant to corrosion and non-reactive with water. Copper is also lower emissivity than aluminum, so the product can easily maintain 0.03 emissivity, even after an anti-patina coating is applied. Sigma is so confident in the continued performance of Copperflect reflective insulation, they stand behind it with a Lifetime Warranty.