Make Things Stick. Add Value.

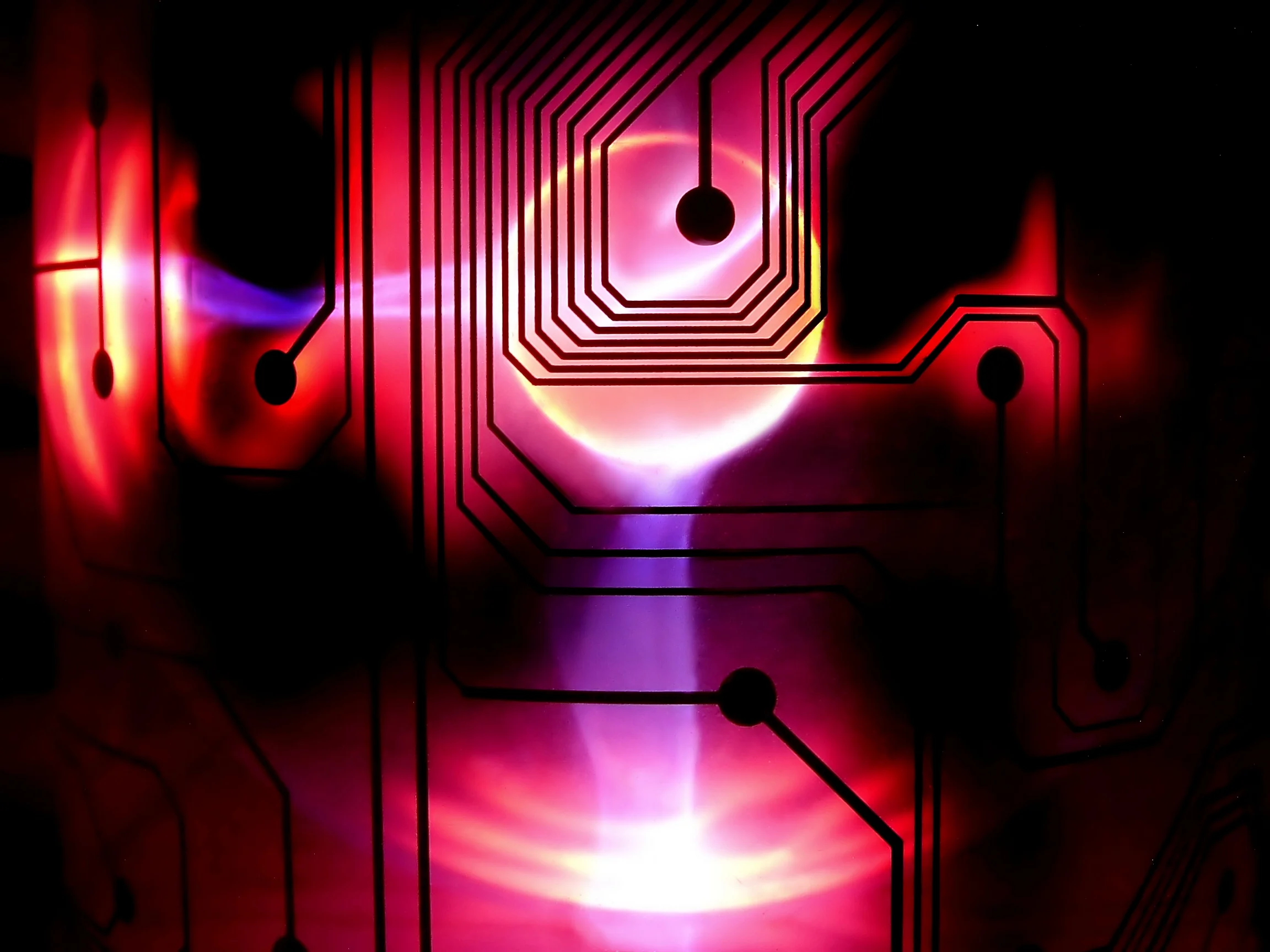

Putting plasma to work.

Sigma plasma treatment systems work by directing a partially ionized medium, comprising a variety of energetic particles (or plasma), to a substrate. The plasma reacts with the substrate surface to remove organic contaminants “graft,” functional groups onto the material surface. Plasma can be used to improve surface wetting, increase bond strength, remove surface contaminates, and deposit highly functional coatings (such as anti-fog, for example).